Bonding in Extreme Conditions: How to Select the Right Adhesive for the Job

Adhesives provide strong, reliable bonds for a variety of applications. But sometimes manufacturing and repair teams have to create bonds in conditions too extreme for standard adhesives. In this post, we break down how extreme conditions impact bonding with structural adhesives.

Market Trends for Adhesives & Extreme Conditions

There are several industry trends and market conditions that are driving the demand for structural adhesives and products that can perform in what we might call “extreme” environments. Because of these trends, manufacturers and repair technicians regularly encounter conditions that exceed the performance capabilities of standard structural adhesives.

Light Weighting

Light weighting is a long-term trend where manufacturers replace heavy material with lighter materials, sophisticated designs, hollow-core materials, and composites. New materials, manufacturing techniques, and green initiatives are pushing product fabrication toward thinner, lighter profiles.

However, this push for light weighting presents challenges for manufacturers and engineers. In many cases, traditional joining methods like welding, screws, and rivets might not be appropriate or even possible in many situations.

Dissimilar Materials

Similar to light weighting, the joining of dissimilar materials is a design trend that strains traditional bonding methods. With so many different materials in one finished product, parts are going to expand and contract in a way hardware and standard adhesives can’t handle.

Intense Temperatures & Humidity

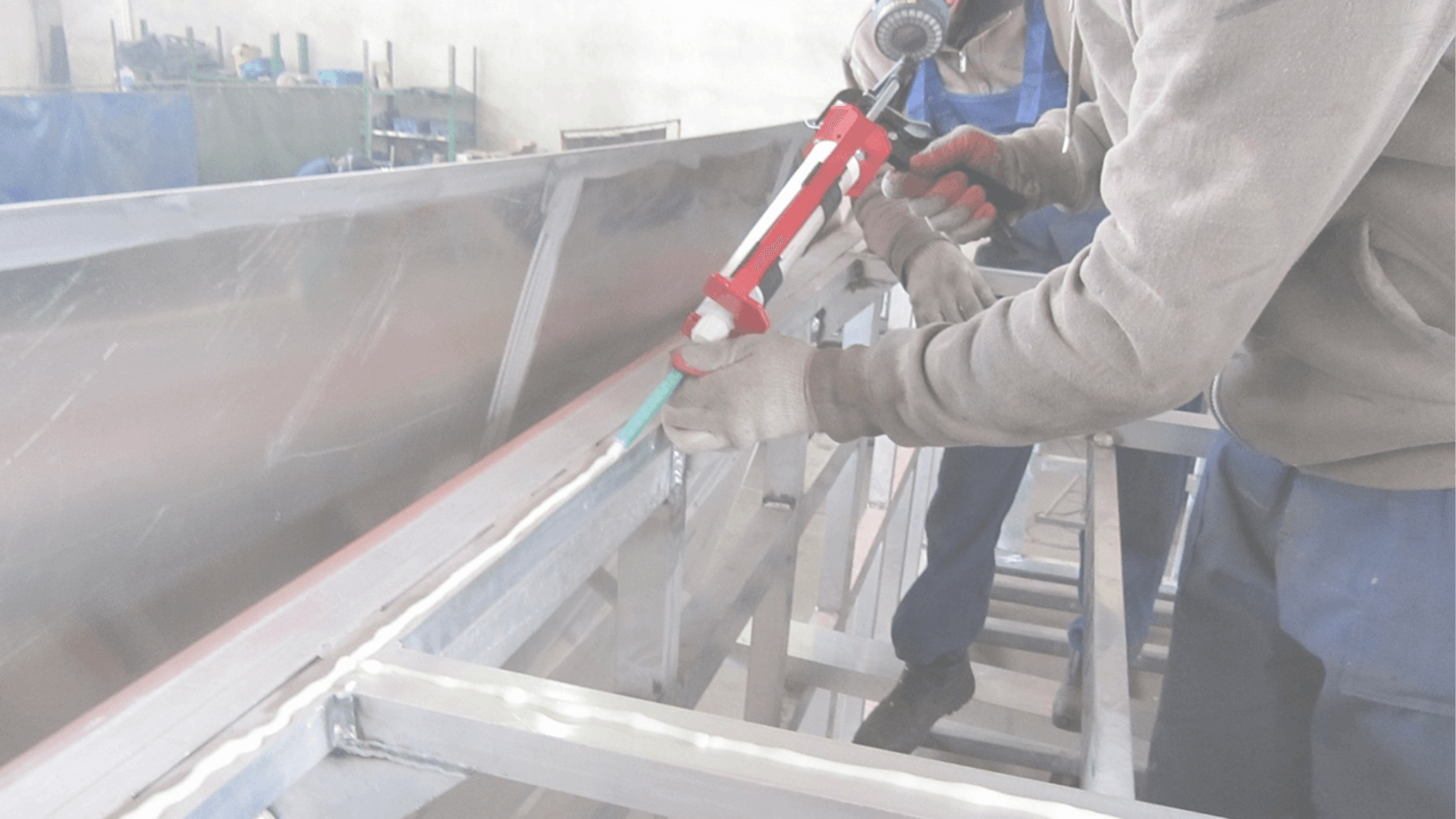

Humidity and high and low temperatures are another challenge manufacturers and repair teams are dealing with. While heat and humidity are certainly not new, what is new is having to conduct repairs on products containing composites, thin gauge aluminum, and dissimilar materials. Repairing these materials in such conditions presents a new type of challenge.

This pressure is being reinforced by an increasing focus on decreasing cycle times so equipment can get back in service with minimal downtime. Whereas in the past a part would be brought back to the shop to be fixed, the new expectation is to repair the product in the field immediately.

Extreme Weather Events

The number of extreme natural disasters is increasing each year. Repair teams across the country are repairing billions of dollars of infrastructure in the fallout of hurricanes, tornadoes, earthquakes, and other extreme events. That can only be possible with structural adhesives strong enough to bond and endure such conditions.

One only needs to look back to the Texas power crisis in February 2021, when technicians had to repair critical infrastructure in severe winter conditions.

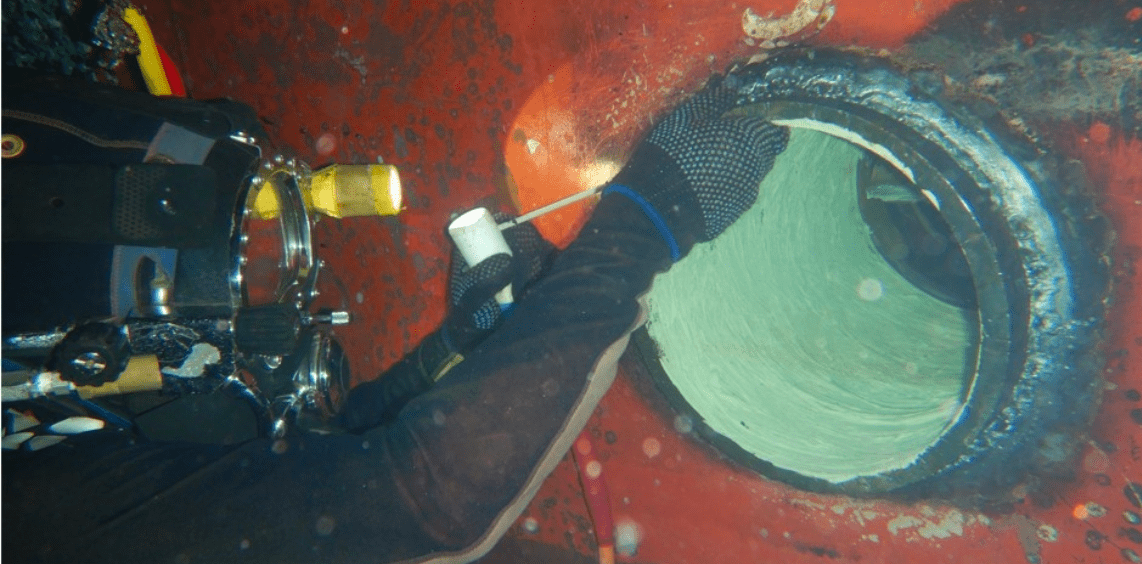

Demand to repair and assemble products in wet, damp or underwater conditions has always existed. But until recently, the products to join materials underwater weren’t available. The continued introduction of new products that can perform underwater will change the game for the marine repair, pool repair, and boat building industries. Gone are the days of having to wait until the material was dry, draining a pool, or moving the product out of the water. Technicians are now looking to complete these tasks in a fraction of the time and with a considerable cost reduction.

Understanding Bonding Conditions

As you can see, there are a number of trends driving manufacturers and repair teams to bond materials in tougher conditions. And understanding the specific conditions you face has a big impact on selecting the right adhesive. So, it’s worth defining both standard and extreme conditions.

What Are Standard Conditions?

Although there are hundreds of thousands of adhesives on the market, each with different specs, it is possible to get a sense of what standard adhesive performance looks like:

- Most structural adhesives are designed to cure in temperatures of 32-110 degrees Fahrenheit.

- After curing they can withstand temperatures below freezing (0-200 degrees)

- Most adhesives require a dry substrate without contaminants during application

- Most adhesives require some amount of surface preparation like drying or primer

What Are Extreme Conditions?

Extreme bonding conditions are any environment that require adhesives to perform in conditions beyond the specifications we defined above. In general, adhesives for extreme conditions can:

- Cure below 32 degrees and above 110 degrees

- Be applied and cure underwater

- Tolerate high humidity

- Tolerate high heat (250 degrees and above) after curing

- Tolerate high pressure

- Provide high resistance to chemicals

- Offer movement capabilities and flexibility

- Tolerate saltwater conditions

- Handle bonding lightweight or dissimilar materials

Working With Standard Adhesives in Extreme Conditions

So far, we’ve reviewed the differences between standard and extreme bonding conditions. But what happens if you use a standard adhesive in extreme conditions?

The bonds for many adhesives can’t survive above their max temperature. In elevated conditions, the performance will eventually decline or fail. This results in a critical joint or connection being compromised.

In colder environments, this means you simply can’t work when you need to.

For example, if an outdoor sign were to fail, a repair company would have to wait for a warm day to repair with a standard adhesive. This means their customers will have to wait indefinitely for the problem to be fixed, potentially creating risks or lost revenue.

When you try to create a bond underwater without the right adhesive, the bonding reaction might not occur. This requires you to reconfigure entire business processes.

If you need to repair a boat, you’d have to dry dock it out of water, which is expensive, creates downtime, and poses an opportunity cost.

If you have to repair a pool, you’ll need to drain it, wait for the surface to dry, apply the adhesive, wait for the adhesive to cure, and refill the pool. This is extremely time-consuming and costs the client hundreds of dollars.

Conclusion

Working with the right adhesive for the job can have a huge impact on the bottom line. For manufacturers and repair technicians who work in extreme conditions, this means significant time, labor, and opportunity cost savings.